What is an RTD?

An RTD (Resistance Temperature Detector) is a sensor that uses the principle that a metal’s resistance is correlated with temperature changes.

The RTD probe is made of a resistance element (typically platinum, nickel, or copper), a sheath, lead wire and a termination or a connector. Some RTDs can be combined with a thermowell for an additional protection from the environment under measurement. For example, a tank with the added benefit of allowing the replacement of the RTD without draining the vessel or system.

An RTD assembly is made of wires of a known resistance connected to a transmitter. This transmitter converts the resistive signal output from the wires to a temperature measurement. RTDs are available in various configurations, wire types, assemblies, and materials to suit the requirements of different applications.

The relationship between resistance and temperature is repeatable throughout the RTD probe’s life cycle. RTDs are formed using metals of positive temperature coefficient, which is why their resistance rises with temperature. The metal’s resistance to the flow of electricity will increase or decrease as the temperature rises and falls.

The benefits of using an RTD compared to other types of temperature sensors are its high accuracy, repeatability and high stability. It is also more linear in its representation of temperature than other forms of temperature sensors, which is why RTDs are the most common form of temperature measurement today.

As seen below, a slight change in resistance changes the temperature measurement drastically.

Understanding RTD Sensors Configurations

2-Wire RTD

A 2-wire lead configuration provides one connection to each side of the sensor. This construction is suitable where the resistance of the run of lead wire may be considered as an additive constant in the circuit, and particularly where the changes in lead resistance due to ambient temperature changes may be ignored. Put simply, a 2-wire configuration is recommended for applications where the accuracy of temperature measurement is not critical. For example, maintaining the water temperature in a tank around 70 degrees Fahrenheit (21.11 °C).

3-Wire RTD

A 3-wire lead configuration provides two connections on one side of the sensor and one to the other side of the sensor. This construction is used for measurements of higher precision and should be preferred to 2-wire for high accuracy applications. The third wire resistance is measured and subtracted from the read value to compensate for the lead wire resistance.

4-Wire RTD

A 4-Wire lead configuration provides two connections to each end of the sensor. This construction is used for measurements of the highest precision. Using four wires, it is possible to subtract the full resistance value from the lead wires.

RTD Accuracy and Standards

The accuracy of the RTD assembly depends on which Class is used as per DIN EN 60751 which displays the tolerance of thermometers (see Table 1). Table 2 indicates the international standards for RTDs along with their average temperature coefficient resistance.

Common Applications and RTD Types

RTDs are extremely versatile temperature sensors and can therefore be used for a wide range of industries and applications. At Intempco, we offer a wide range of RTDs to ensure we meet different industrials standards and needs. Industries using RTDs for temperature measurement include:

- Pharmaceuticals

- Oil & gas

- HVAC

- Mining

- Food and beverage

- Natural gas

- Refrigeration

- Aerospace

- Defense

These sensors are often used for applications that require temperature monitoring of fluids, air, process heat exchangers, solids, ceramics, metals and oils, among others. RTDs need to fulfill the requirements of these industries and applications, which is why selecting the right type is essential.

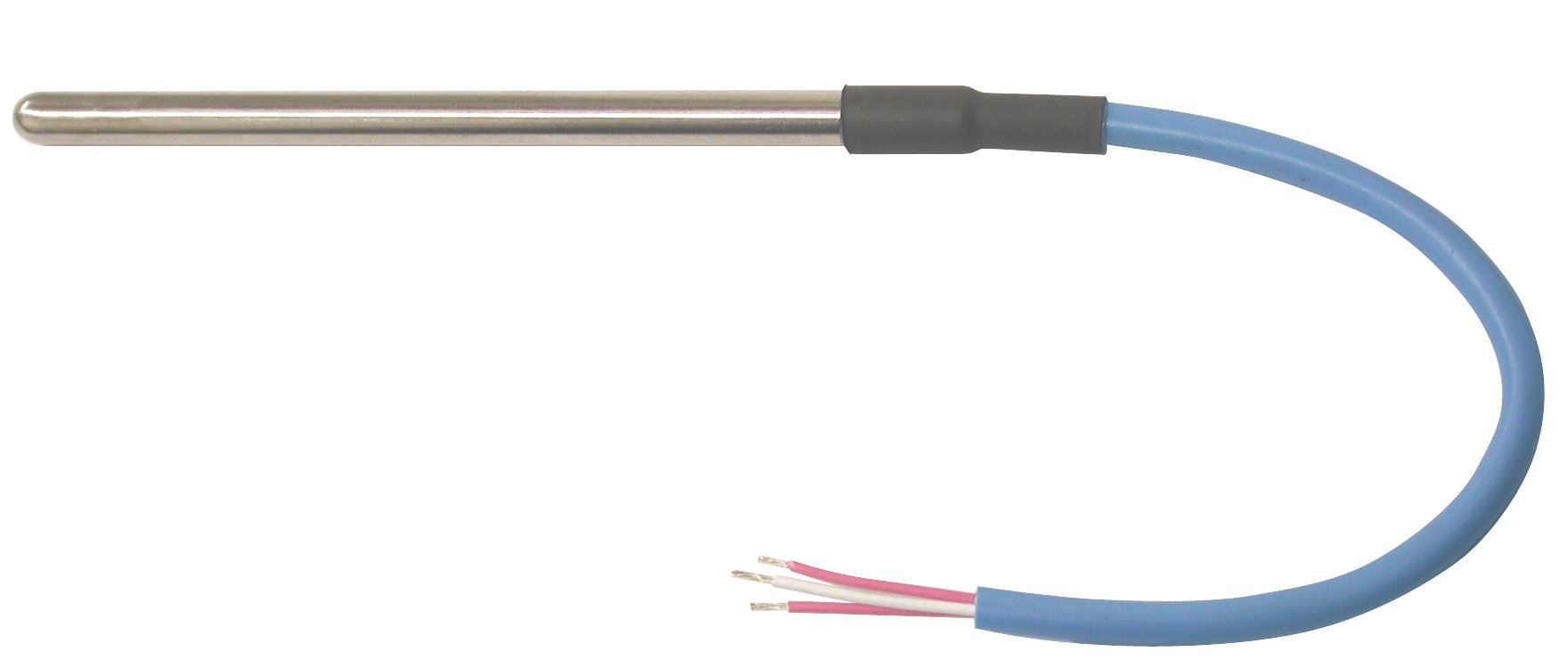

RTD Probes

Probe type RTDs are sensors consisting of a probe section of various diameters and lengths which are terminated either with extension cables or an electrical connector attached directly to the probe.

Intempco’s R03 Capsule RTD with no Transition Extension Cable and Adjustable Compression Fitting

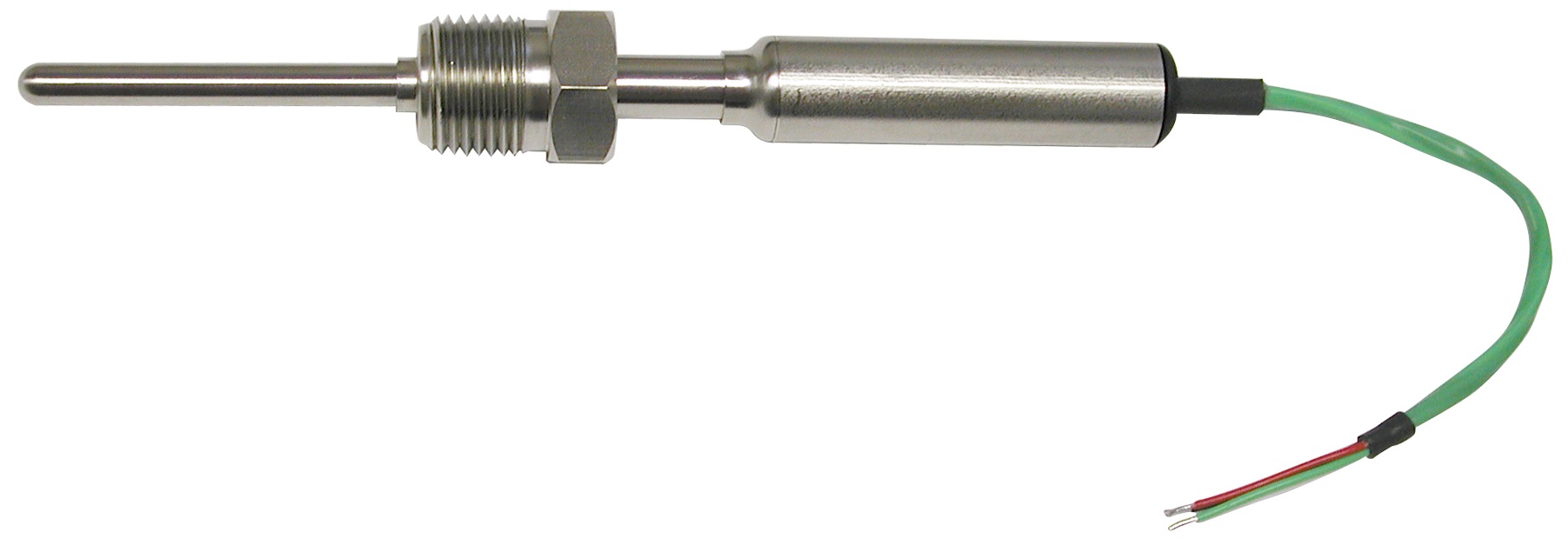

RTD Assemblies with Connection Head

RTDs can be assembled with a connection head when mechanical and environmental protection for the electrical connection is necessary. Examples include high humidity or dusty environments. Hockey puck-style temperature transmitters can also be mounted inside these enclosures.

The process connection on these assemblies can be supplied for direct mounting into a process, or spring-loaded for mating with thermowells and protection tubes.

Intempco’s R50A RTD with Connection Head for Direct Immersion

Sanitary RTD

Sanitary RTDs are used by industries that require the highest standards when it comes to preventing contamination and complying with regulatory authorities like the FDA and the USDA. The pharmaceutical, food & beverage and dairy industries are prime examples of industries that use sanitary RTDs.

This type of RTD features a hygienic Tri-Clamp. Different materials are typically used for the connection head for sanitary applications. Polypropylene, stainless steel, bakelite and Teflon are some common connection heads.

RS80 Sanitary RTD with Connection Head

MIST Microprocessor Integrated Sensor Transmitter

The MIST is Intempco’s patented Microprocessor Integrated Sensor Transmitter. The MIST is a complete temperature measurement solution that combines an RTD probe with a miniature programmable temperature transmitter into a single unit that doesn’t require a connection head, allowing for a small, compact sensor. The MIST Series come factory calibrated to the customer’s specified range and can be re-calibrated and re-programmed by the end user.

The adverse effects of electrical noise can be reduced, and lead wire lengths extended with Intempco’s MIST RTD technology.

Intempco's MIST M23 RTD Temperature Transmitter Sensor Probe, welded fitting and lead wire cable

Digital Temperature Gauges

Intempco’s Digital Temperature Gauges (DTG) take the MIST technology further by incorporating an LED or LCD four-digit display for easy temperature reading and monitoring. DTGs are digital RTD thermometers and a complete solution for most industrial temperature monitoring and temperature indicating applications. Models with the programming option can be re-calibrated by performing a one-point or two-point calibration using known temperature standards with Intempco’s DTG programming kit.

The RTD element used is Pt-1000 standard accuracy to DIN IEC 60751 Class A. DTG can be made available with an additional RTD output. This feature allows a single process connection to be used for indication of temperature and for remote indication, recording, or controlling. The electrical connector, a flexible cable or a Micro-DC male plug are made available from the stainless housing for the optional RTD output.

DTG03 Digital RTD Sensor Probe, Compression Mount

How To Select the right RTD?

RTDs are one commonly used temperature sensors because they provide accuracy, stability and repeatability, in addition to being extremely versatile. Although the value of this type of sensor no longer needs to be proven, it is worth mentioning that a clear understanding of the application’s requirements is necessary prior to ordering an RTD. Take some time to speak to an expert if you need some guidance to choose and customize the right RTD for your application.

Explore Intempco's sensors and products:

|

|

|

|

|