vendredi 25 septembre 2020

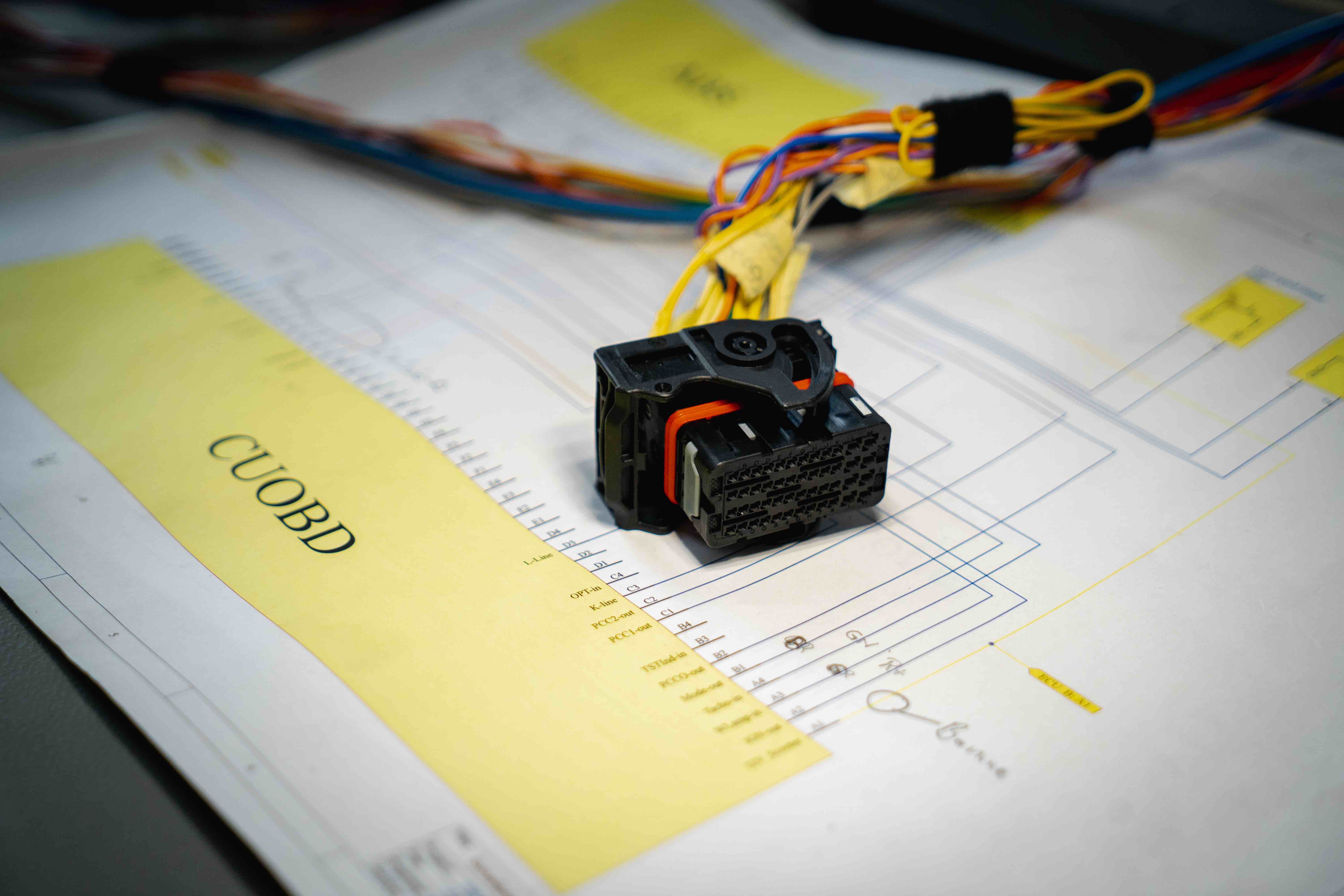

10 Tips to Save Time Wiring

Wiring for control panels and other industrial applications can be a complex and time consuming process. Making sure you plan out and organize your wiring job will save you time and effort down the line. Follow these ten tips to get the job done efficiently.

Before You Start: Safety First!

Before you start wiring, test wires and devices and check amperage ratings to prevent electrical shock and overloading the circuit.

Get Organized and Get to Work

1. Have all the preparation work done before starting the wiring job

This includes drawings, education, layout, materials, equipment and more. This alone will be an enormous time saver.

2. Always have the required equipment

The basics include wire strippers, utility knife, screwdrivers, pliers, cutting pliers and a multimeter.

3. Identify each wire with labels

Make a cut list and label your wires ahead of time. The more wires you have, the more time this step will save you down the line.

4. Unbundle each line and cut once at destination

When running wires to the same location, unbundle each line together and run them together. Then cut all wires to length once at the destination.

5. Wire to your control panel, then cut

When possible, wire one end to your control panel to secure it. Then, run the other length to your component and cut.

6. Keep track of your work in progress

As you wire from your drawing, use a highlighter on the drawing as you install each wire. This helps to keep track and stay organized.

7. Do one thing at a time

Don’t try to do too much at once. You will waste time by leaving items undone and needing to set things back up.

8. Choose the appropriate wire size

Know your safety requirements for wire and components. Choose your wire size appropriately. Do not cheap out and use thin wiring. Most industries value long term value compared to short term saving.

9. Don’t put your tools away until you’re positive the job is done

This one may seem obvious but it is a common mistake we’ve seen. So many times we put the tools away before everything is completely finished. Having to go back and find the tools you need is a waste of time that is avoidable.

10. Don’t aim for perfection

If things are not perfect, that’s all right. Do not try to re-modify your work if it's not necessary. If your control panel wiring works well, is safe and the right wires were used, you can live with the result. Save time and move on to the next job.