mercredi 5 août 2020

All About Digital Temperature Gauges

what is a digital temperature gauge?

A Digital Temperature Gauge (DTG) is a digital RTD thermometer that is a complete solution for most industrial temperature monitoring and temperature indicating applications.

Simply put, it is the modern version of a bi-metal, liquid bulb, mercury or capillary gas thermometer. It has enhanced accuracy and can be scaled to the required temperature range. It combines the RTD sensing element and transmitter to output the standard 4-20mA industrial output.

Have a look at Intempco’s digital temperature gauge and RTD sensor probes, here .

when is it best to use a digital temperature gauge instead of a bimetallic or glass thermometer?

The digital temperature gauge, also referred to as a digital thermometer, offers higher accuracy than bimetallic gauges and glass thermometers.

The DTG can be viewed as the modern version of a bimetallic temperature gauge. Basically, it is the next generation of thermometers. It leverages the advancements in electronic conditioning and signal processing to give a more accurate reading.

Instead of a standard +/- 1% full span guaranteed accuracy of bimetallic thermometers, it is acceptable to expect +/- (0.36 + 0.002 x |T - 32|℉) (METRIC: +/- 0.1℃ + 0.20%FS) of reading from a digital temperature gauge. If your range is 32℉ to 392℉, then the bimetallic sensor’s accuracy will be +/- 35.6℉, whereas the DTGs would be only +/-32.9℉. That’s an improvement of +/- 34.7℉.

That does not include the added accuracy of being able to properly read the temperature. Glass thermometers and bimetallic temperature gauges are often misread due to the construction. They depend deeply on the ability to see the dial of the bimetallic gauge or the fluid in the thermometer, which isn’t always easy to see.

With the DTG, the user can easily read the temperature measurement with the large four-digit LED or LCD display. Have a look at Intempco’s bimetal temperature gauges here.

how is a digital temperature gauge different from a bimetallic and glass thermometer?

The major difference between digital temperature gauges/digital thermometers and bimetallic temperature gauges is how they physically detect temperature and how they are powered.

Bimetallic temperature gauges use a bimetallic helix strip composed of two different metals, normally Copper and Invar, that are fused together. They expand and contrast depending on whether the temperature is increasing or decreasing. The metals are mechanically attached to the dial.

Essentially this will last until there is a mechanical failure. In their basic form no power source is required. More recently, manufacturers have added the ability to send outputs and thus have added small power requirements.

DTGs are constructed using the principle of a resistive temperature detector (RTD). That is, a junction of two different metals which will vary the resistance in the circuit depending on temperature. Here, there is the requirement for a power source. It can be a battery or an external power supply.

Fundamentally, bimetallic temperature gauges and DTGs are different, but act in a similar way of monitoring and indicating the temperature.

how to properly install a digital temperature gauge

Digital temperature gauges are very simple to install. It is dependent on which type of process connection is required in your application. The options for fittings include welded fitting, compression and sanitary. Then there is also front or back flange mounting and direct mounting with rigid stem.

So, you must know what is required in your application. If it is a brand new design, then compression or sanitary process connections are recommended due to their adjustability and ease of use in installation.

As an example, to install a welded fitting type DTG, you must first choose the right size and material. To do this there are three steps:

-

Choose the Fitting Type (i.e. NPT, UNF, Standard..etc)

-

Choose the Fitting Size ( ⅛, ¼, ½ ..etc)

-

Choose the Fitting Material ( Stainless Steel, Brass, Steel..etc)

No matter what fitting type is chosen or the material, it is important to know the proper torquing requirements for the process connection. For a typical stainless steel NPT fitting it is acceptable to hand tighten then turn 1 ½ turns with a wrench. This could change depending on the material that you're mounting too.

-

Initial Inspection

Every gauge will arrive factory calibrated and scaled to the selected temperature range.

Once you’ve received the digital temperature gauge and removed the packaging you should still verify that it works properly before installing it. This can save some heartache in the case that the gauge was possibly damaged during shipping. All that takes is a visual inspection and a verification of zero degrees. Check the probe to make sure there are no deformations.

Next, create a standard ice bath and allow the gauge to stabilize within. Give it 15-20 minutes to ensure it has reached thermal equilibrium. If there are no issues with both cases, then it is ready to install.

If the probe was damaged, then you should try to return it to the manufacturer. If the temperature is not within the specified tolerance during testing in the ice bath, then you could be able to adjust the “zero” of the sensor. In some cases, that can be done by a potentiometer or through software. If neither options are available, then contact your manufacturer for the next steps.

-

Installation

The installation of the gauge is no different than the installation of other equipment with process connections. If you have experience with fittings or plumbing processes, then it's very similar to that. The only exception is having a dedicated location for the head of the DTG.

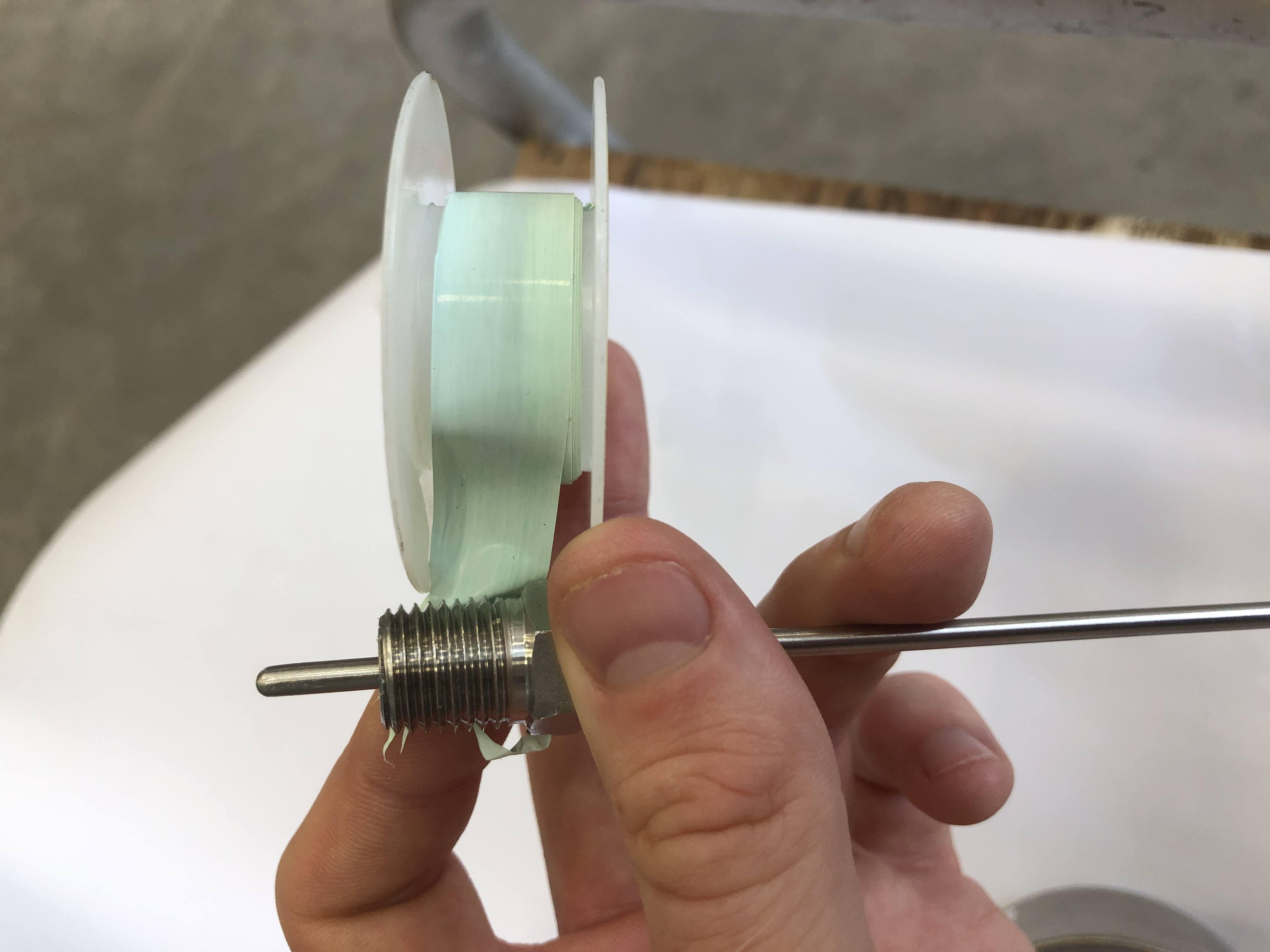

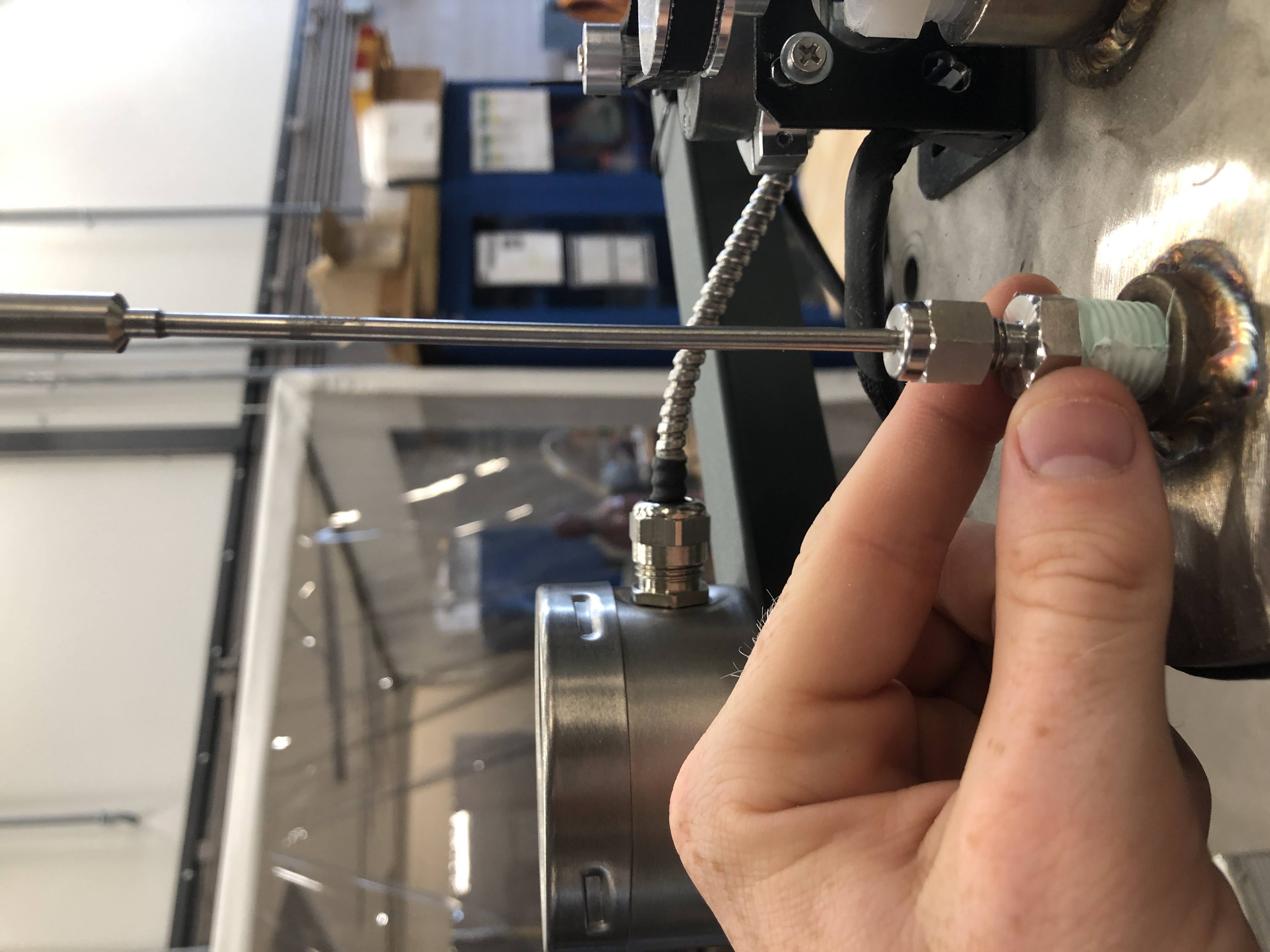

Begin by wrapping the threads of the fitting with some teflon tape. The recommended amount is three full turns. If you have sealant paste, apply ¼” onto the tape. This will ensure a proper seal and will prevent any leakage.

Next, hand tighten the gauge into the desired location. Avoid holding the threads because you risk getting some steel shavings into your fingers, which can be painful. Hold it by the hex fittings when possible.

The last step is to use one or two wrenches to tighten the fitting to the desired depth. Do not use the head of the gauge to help you turn the fitting into place. You should try to brace the movement by a second member of the shaft of the gauge.

-

Final Inspection

Upon installation of the DTG it is important to make sure you got it right. That means having a good idea how to verify that the system is performing properly. For this, you will need to use half experimental and half judgment to determine if everything is working well.

If you have numerous temperature reading locations, you should be able to logically determine if one is not set up correctly.

If the DTG is the only temperature reading on the system, then toggle the temperature a little and see that your DTG is adjusting properly. Make sure the probe tip is at the point of contact for your application.

DTGs are delivered factory calibrated and almost 99% of the time they will work perfectly, but failure to properly install them can lead to inaccurate readings.

applications of digital temperature gauges

Industrial

Each sensor provides its own complex and unique design challenge. From sensors in bridge supports deep below the Confederation Bridge, to engine testing for NASA, DTGs rise to every challenge.

DTGs offer a broad range of industrial temperature configurations. They can be customized and specialized for your specific application. The wide range of fittings and technology can fulfill all of your sensor needs.

The digital display is great for dimly lit areas or extremely important temperature readings. They are much more noticeable than the former technologies.

Fuel/Oil

This continuous fuel/oil level sensor measures a change in resistance based on the liquid in direct contact with the probe. It includes an industrial level transmitter that converts the highly accurate signal to a linear 4-20mA analog output to monitor and control biofuel, diesel, hydraulic oil or food oil.

DTGs are currently used to monitor diesel fuel temperature for stationary or mobile generators. This temperature gauge is shock resistant and very rugged. There are no moving parts. Splashing or wave action will not damage the gauge.

HVAC

For HVAC systems to operate in the 90 percentile of efficiency, proper control is crucial to the performance. Imagine a difference of 3℉ or 4 ℉ when operating a building of multiple hundreds of thousands of square footage. The cost savings due to proper heating and cooling measurements is enormous.

DTGs are used everyday to measure precisely the air temperature inside buildings. They have extremely high accuracy of +/- (0.36 + 0.002 x |T - 32|℉).

practice application

Use DTGs to Determine the Temperature Change

DTGs are ideal when it comes to measuring a temperature drop. Use two DTGs if your temperature drop occurs through a pipe or use one DTG if it happens in a reservoir.

calculation

Temperature Drop due to Pressure Drop

Your gas system is initially at shop air pressure of 100psi (689kPa). The air temperature within the system is at 86℉ (30 ℃). Assuming your volume stays the same, but you drop the pressure down to 95psi (654kPa) for a special application, what is your final temperature in the system?

Answer

Using Boyle’s and Charles’ Law

T1 =(86℉-32)59+273.15=303K

P1 T1 = P 2 T 2

100psi303K=95psi T2

100psi303K=95psi T2

0.330psi/K=95psiT 2

T2 =95psi0.330psi/K

T2 =287K