Monday, 14 September 2020

Sanitary Temperature Sensors used in Development of COVID-19 Vaccine

The race to develop a vaccine for SARS-CoV-2 (COVID-19) could not be more important for global stability. Right now, companies and individuals are supporting these companies to accelerate their process. Here's a look at what we can expect from the sensors' industry in the face of this challenge.

The stages of any vaccine development are:

- Exploratory

- Pre-Clinical

- Clinical Development

- Phase 1

- Phase 2

- Phase 3

- Regulatory Review and Approval

- Manufacturing

- Quality Control

At the moment, we are deep into clinical trials in North America and we are gearing towards phase 3. This means that soon enough there will be a need for high quality sanitary sensors for the large manufacturing facilities.

How Are Sensors Used in the Vaccine Production and Distribution Process?

To measure the required temperature during development and to maintain the “cold chain”, sanitary temperature sensors must be used. The cold chain is any process used to transport, store, or handle vaccines along its route to distributors.

Temperature sensors play a crucial role in the distribution of vaccines. This is why digital temperature gauges with an accuracy of at least 32.15℉ (0.1℃) are recommended for use. The temperature is to stay between +35℉ and +46℉ (2℃ to 8℃). Vaccines that are not kept within this temperature range from manufacturing until the point of administration are at higher risk of being damaged and ineffective.

Selecting the right sanitary temperature sensors is a large part of creating an effective vaccine.

What are the Features of a Sanitary Sensor?

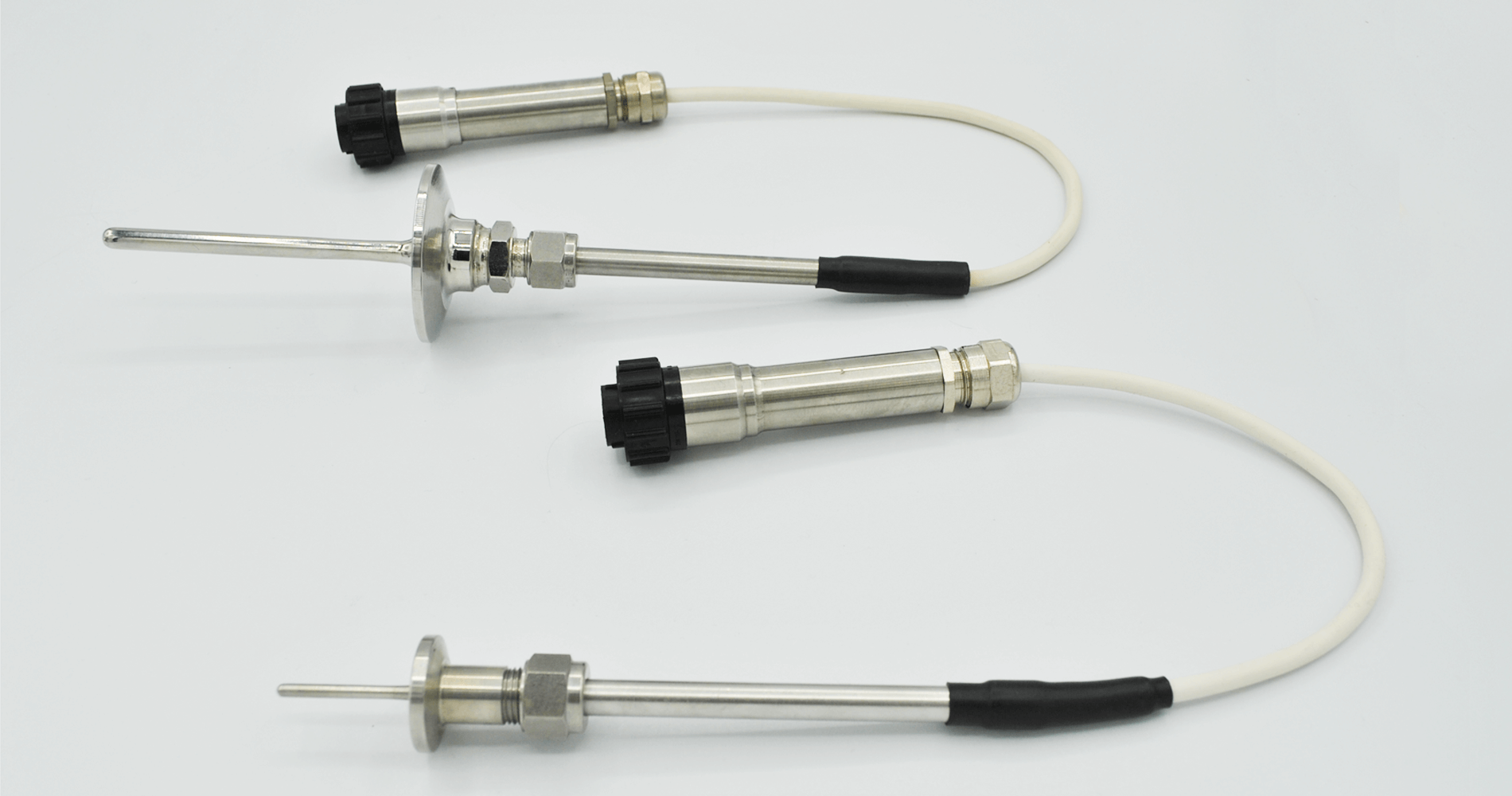

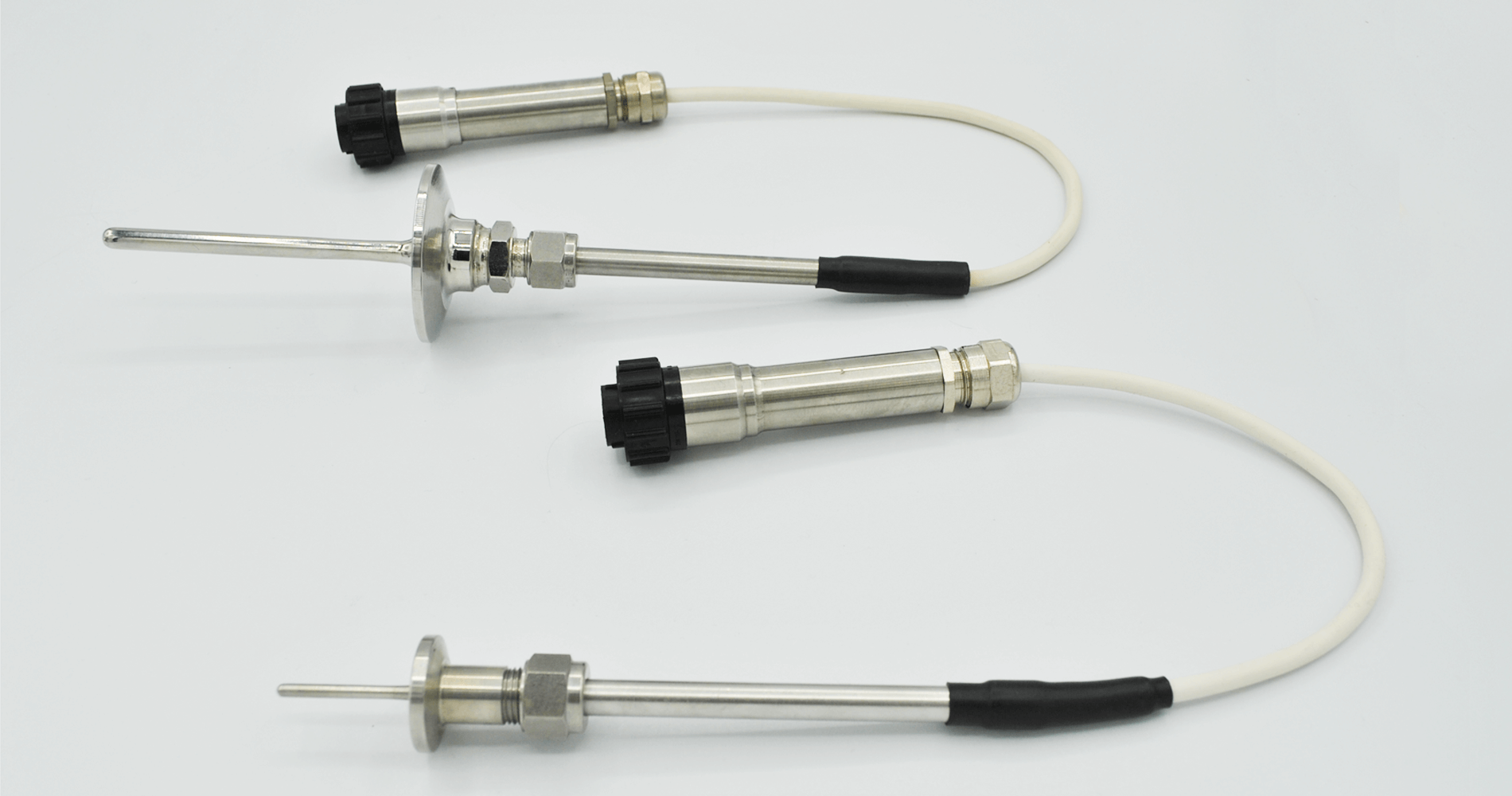

When you look at a sanitary sensor, the first thing you may notice is a large cylinder shape flange above the probe of the sensor. This is a hygienic clamp union or tri-clamp and is a part of the clean-in-place operation. There are three main features that separate a sanitary sensor from a standard sensor: Process Connection Types, Material and Standards.

Process Connection: Hygienic Clamp Union (Tri-Clamp)

A process connection is the area of the sensor used to connect it to the application. In standard applications it is mostly fittings. There are many types of fittings — NPT, compression, UNF — and they come in all different sizes. Whereas, sanitary sensors are dominated by hygienic clamp unions. This is because they reduce the labour time and improve the efficiency of cleaning the sensors. The design also aids to create a liquid seal. The flanges range from ½” to 3” in diameter.

Materials

Material selection is extremely important with sanitary sensors. Contamination can occur if your sensor material lacks any of the following traits: smooth, free of cracks, non-reactive, non-absorbent, durable, and can be easily cleaned.

Any coatings are to maintain corrosion resistance and avoid chipping or pitting of any sort. This applies to other industrial practices used during fabrication such as welding and soldering.

Stainless Steel 316 is often the most desirable material to be used in sanitary applications because of its high corrosion resistance and durability. This is created by the increase in molybdenum compared to SS304. There are higher qualities of stainless steel that can be used in extreme scenarios, but this is in rare occasions.

Teflon is also a great choice for sanitary sensor materials as it is the plastic with the lowest coefficient of friction and is very unreactive. That is why is commonly used in chemical applications but has temperature limitations around 500℉ (260℃).

Titanium, Platinum and Gold are among the materials suitable for sanitary applications but generally the costs make them unworthy of selection.

Standards

The certification for sanitary sensors is 3-A Sanitary Standards approval to which hygienic practices are enforced during design and manufacturing of sanitary equipment.

3-A Sanitary Standards date back to 1920. This was when industrial systems were being striped by hand, cleaned and put back in place. This led to a lot of wasted time and losses. It was later made an industry standard in 1956.

There are other organizations such as National Sanitation Foundation and Underwriters Laboratories that also provide forms of certification.

Find out more about Intempco's line of 3-A Sanitary temperature sensors.